24 ก.ย. AI Unboxed: 5 Groundbreaking Packaging Innovations

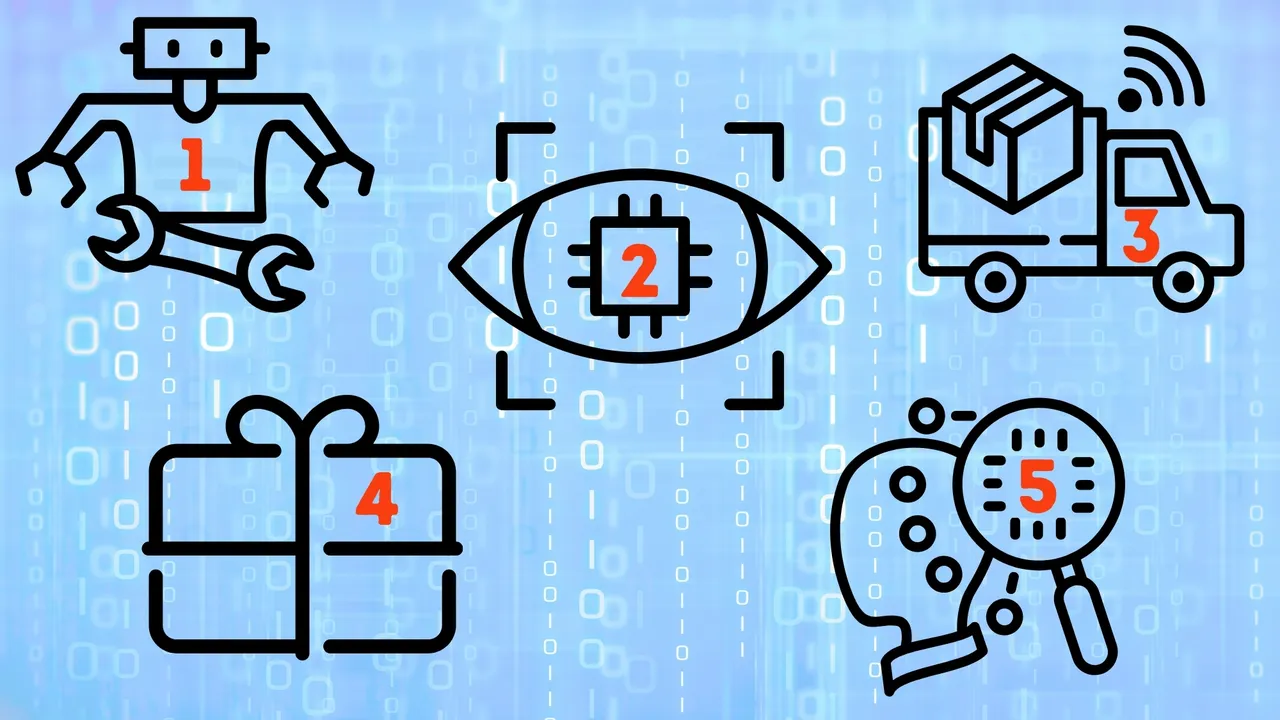

Discover how artificial intelligence is revolutionizing the packaging industry. Explore cutting-edge AI applications in predictive maintenance, quality control, supply chain optimization, and more.

At a Glance

- AI-powered sensors and vision systems enhance predictive maintenance and quality control in manufacturing processes.

- AI-driven supply chain optimization improves traceability, compliance, and demand forecasting in pharma and elsewhere.

- AI enables personalized packaging, empowers workers, and drives future trends like smart packaging and hyper-automation.

Artificial Intelligence (AI). It’s the concept that’s been knocking around for centuries, living rent-free in the imaginations of everyone, from philosophers to sci-fi writers. Lately, though, it feels like AI has burst out of its conceptual cocoon and into our everyday reality. We’re hearing about it everywhere — and for good reason. Technology is advancing at a pace we can barely keep up with, and manufacturers are leveraging AI to automate processes, improve efficiencies, and reimagine how work gets done.

Now, depending on who you ask, AI is either the next big thing or the harbinger of humanity’s doom. (Shoutout to Hollywood for all the dystopian narratives!) But, regardless of how you feel about it, AI isn’t just a buzzword anymore. It’s a broad, fascinating field that pulls inspiration from disciplines like computer science, data analytics, neuroscience, and even ethics. And, it was an obvious trend I was confronted with during my time at last year’s Pack Expo.

Here are just a few things about AI that caught my attention at the show, including how it’s changing the packaging and processing industry.

AI-powered sensors to refine predictive maintenance.

We are all aware of the nightmare caused by equipment downtime, leading to lost productivity, missed deadlines, and a whole lot of stress. AI-powered sensors and machine learning algorithms allow manufacturers to monitor equipment health in real time and predict when a machine might fail. This proactive approach helps reduce downtime, optimize repair schedules, and save money.

One example is a bottling line equipped with AI-drive sensors. The sensors detect subtle changes in vibration, temperature, or sound that might indicate a problem. The system then alerts operators, who can address the issue before it becomes a full-blown crisis.

AI vision systems to transform quality control.

Nowadays, quality control is non-negotiable. Consumer expectations are higher than ever, and AI-powered vision systems are using machine learning to analyze images of products on the line and identify imperfections in real time.

One company that caught my eye at Pack Expo was Oxipital. They developed an AI-vision platform that addresses the high-variability challenges in manufacturing environments. Manufacturers gain actionable insights from real-time data collected around:

-

Defect Mitigation: Identify and classify defects at any production stage to pinpoint origin, optimize quality, reduce waste, and improve margins.

-

Quality Assurance: Identify, measure, and track a wide range of product attributes to ensure your products are in spec at any point in their production process.

-

Live Monitoring: Gain real-time visibility into production quality to respond more quickly.

-

Continuous Improvement: Act on real-time quality monitoring data to respond faster, minimize downtime, and improve efficiency.

AI-driven supply chain optimization.

The supply chain is the backbone of any manufacturing operation, and AI is helping to make it stronger, smarter, and more resilient. By analyzing vast amounts of data, AI can optimize inventory levels, forecast demand, and identify potential disruptions before they happen.

A great example of this lies within the pharmaceutical industry, where the supply chain is an intricate web of processes that require precision, security, and compliance at every step. As regulations tighten and the demand for transparency grows, companies must find innovative solutions to ensure end-to-end traceability, optimize efficiency, and protect consumers.

Enter the ACG Life Sciences Cloud (ALSC), a platform designed to tackle these challenges head-on.

The ACG Life Sciences Cloud provides real-time visibility, allowing stakeholders to monitor every stage of the supply chain.

-

Real-time Tracking: The ALSC dashboard provides a live view of pharmaceutical products as they move through the supply chain. This transparency helps identify potential bottlenecks, delays, or security threats before they become major issues.

-

Regulatory Compliance: With strict global regulations such as the Drug Supply Chain Security Act (DSCSA) in the U.S. and the Falsified Medicines Directive (FMD) in Europe, compliance is a significant challenge. ALSC automates data collection, reporting, and auditing, making it easier for companies to meet serialization and traceability mandates without the headache of manual tracking.

-

Data Security and Integrity: The platform employs blockchain technology to ensure that all recorded supply chain data is tamper-proof, significantly reducing the risk of counterfeit drugs entering the market. This level of security builds trust among manufacturers, regulators, and consumers alike.

Beyond compliance, traceability is critical for product recalls. ALSC allows companies to quickly pinpoint affected batches, minimizing the impact on patients while maintaining regulatory adherence.

On the demand forecasting side, ALSC leverages predictive analytics to improve inventory management and align production with real-world needs:

-

Historical Data Insights: The platform analyzes past sales and production trends to create more accurate demand forecasts, preventing both overproduction and stockouts.

-

Predictive Analytics: Machine learning models refine forecasts by factoring in market conditions, consumer behavior, and external variables, enabling smarter production planning.

-

Dynamic Adjustments: Near real-time demand updates ensure manufacturers can respond to sudden shifts, improving agility in a rapidly evolving market.

AI personalization and customization.

Today’s consumers want products that feel tailor-made for them, and AI helps businesses analyze customer preferences and purchasing behaviors. This allows personalized packaging and product offerings at scale.

For instance, a beverage company might use AI to design limited-edition packaging that resonates with specific demographics. Or a snack manufacturer could tweak flavors based on real time consumer feedback.

AI-powered tools for tomorrow’s workforce.

Contrary to the fear that AI will replace human workers, it’s often more about augmentation than elimination. In the packaging and processing industry, AI-powered tools are helping workers do their jobs better, faster, and safer.

Think of an AI-driven software platform that provides step-by-step instructions for machine operators, reducing errors and training time. Or consider a cobot, or collaborative robot, that works alongside humans, handling repetitive tasks so workers can focus on more complex responsibilities.

Redzone introduced Champion AI, its latest suite of capabilities focused on enabling the connected worker with AI-generated assistance. This platform delivers predictive and prescriptive analytics through generative AI to improve productivity and engagement on plant floors. With its pragmatic approach, Champion AI tackles real-world problems that occur daily, including:

-

Assess performance and prepare for your day with plant summarizations.

-

Lower costs for changeovers with predictions on run completion and changeover times.

-

Predict run problems and receive prescriptive recommendations to avoid them.

-

Improve productivity and outcomes through recommendation prompts for workers to create an action item for fixing a top loss or triggering a safety incident form for a near miss.

AI isn’t just about automation; it’s about enabling people to thrive.

Challenges and considerations.

There’s no question that the potential of AI is enormous; however, it’s not without its challenges. Here are a few things we all need to keep in mind:

-

Data Privacy and Security: AI thrives on data, but with significant data comes great responsibility. Manufacturers must ensure that sensitive information — whether it’s customer data, supplier details, or proprietary algorithms — is protected from breaches and misuse.

-

Cost of Implementation: AI technologies can be expensive to implement, especially for small to mid-sized businesses. The initial investment in hardware, software, and training can be daunting, even if the long-term return on investment is promising.

-

Workforce Upskilling: As AI tools become more prevalent, the workforce will need new skills to use them effectively. This requires ongoing training and education, which can be both time-consuming and costly.

-

Ethical Considerations: From algorithmic bias to job displacement concerns, AI raises important ethical questions. Companies must navigate these challenges thoughtfully, ensuring that their AI initiatives align with their values and expectations.

The future of AI in packaging and processing.

So, what’s next? Here are a few trends to watch out for:

-

Smart Packaging: AI enables the development of “smart” packaging that does more than just protect a product. Imagine a food package that uses AI to monitor freshness, alerting consumers when it’s time to eat or toss. Or packaging equipped with augmented reality (AR) features that enhance the customer experience.

-

Sustainability: As the industry prioritizes sustainability, AI plays a crucial role. From optimizing material usage to reducing waste during production, AI helps companies meet their environmental goals while maintaining profitability.

-

Hyper-Automation: Automation is evolving into hyper-automation, where AI works alongside robotics, the Internet of Things (IoT), and other advanced technologies to create fully integrated, self-optimizing production lines.

-

Human-AI Collaboration: The future isn’t about humans versus machines; it’s about humans and machines working together. Expect to see more tools and platforms designed to make AI accessible and user-friendly, empowering workers at all levels.

Final thoughts on the AI transformation.

AI is transforming the packaging and processing industry in ways we’re just beginning to understand. From predictive maintenance to personalized packaging, the possibilities are as exciting as they are endless, and it’s up to manufacturers to harness them ethically, sustainably, and inclusively.

Whether you’re an AI enthusiast or a skeptic, one thing is clear: the future of packaging and processing is smarter, faster, and more innovative than ever before. And AI is leading the charge — one algorithm at a time.

Sorry, the comment form is closed at this time.